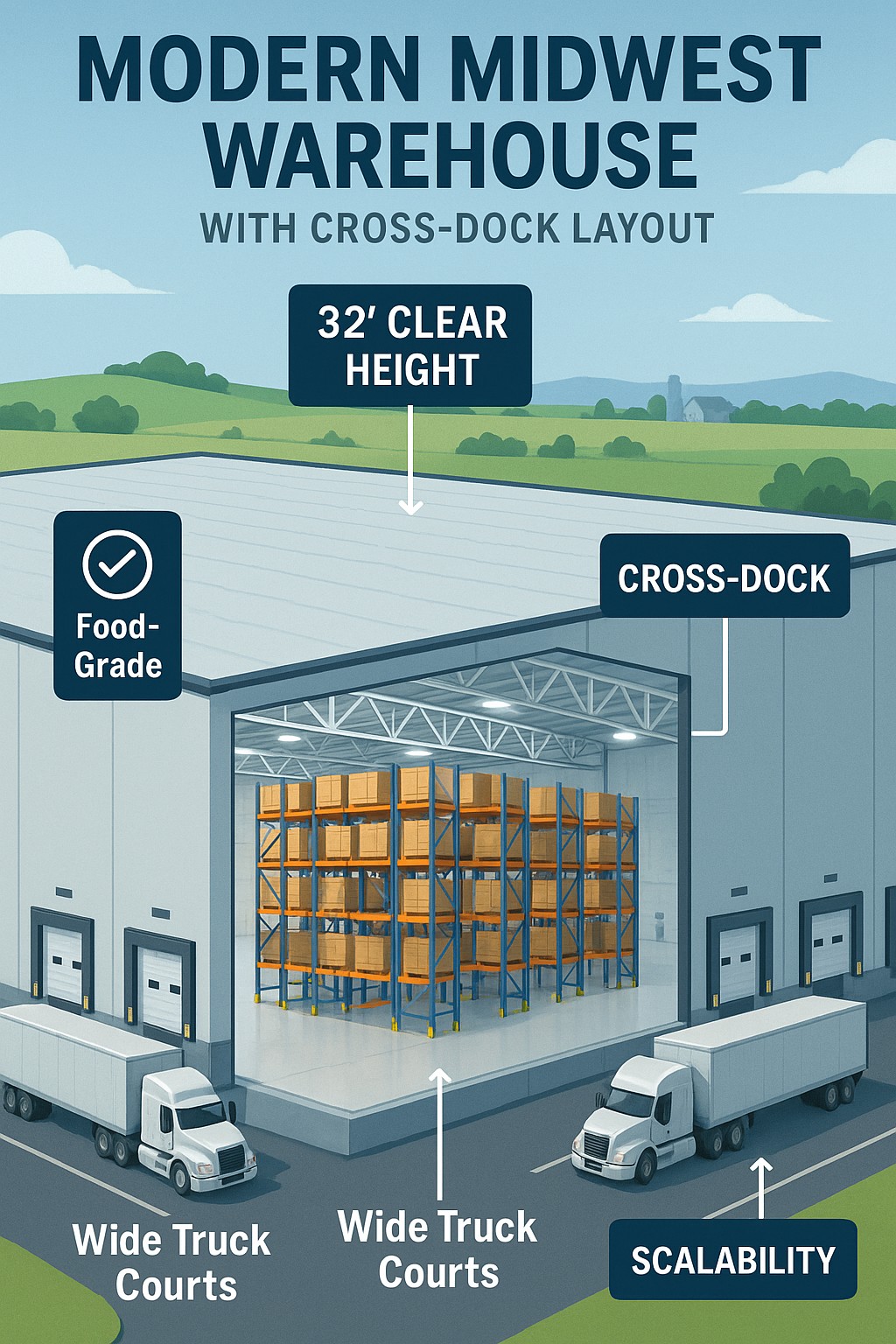

The Right Building Can Accelerate Your Growth

In today’s constrained industrial real estate market, the right facility isn’t just about square footage—it’s about speed, flexibility, and future-proof design.

Whether you’re expanding a food-grade operation, scaling 3PL capacity, or optimizing regional distribution, Midwest speculative warehouses must deliver operational readiness from day one.

So, what should site selectors and operations leaders prioritize in 2025–2026?

The building’s internal geometry determines your efficiency long before your first shipment moves.

Look for:

Keller’s new 150,000 SF Peru, IN facility checks every box—with a modern cross-dock layout optimized for high-turn environments.

Dock design is where speculative buildings often cut corners.

For fast-turn operations, look for:

At Keller’s Peru site, every dock is designed for food-grade and high-volume users, ensuring that tenants can plug in and operate from day one—no retrofit required.

Ceiling height defines cubic capacity and racking potential.

The modern Midwest standard has evolved from 28’ to 32’ clear heights or higher, giving operations the flexibility to scale without relocating.

Peru’s 32’ clear height supports dense racking, advanced material handling systems, and automation readiness.

Whether or not your current product requires it, food-grade construction adds value, safety, and flexibility for the long term.

The Peru facility’s food-grade specifications—from sealed floors to enhanced ventilation and hygienic materials—make it ideal for food, beverage, and consumer goods tenants alike.

Built for Scalability. Designed for Real Operations.

A speculative building should never feel speculative—it should feel ready.

Keller Industrial Properties and ARCO designed this facility for immediate readiness and long-term growth, built to support logistics users who can’t afford to wait for new construction cycles.

Ready When You Are — 150,000 SF Move-In Ready. Built by Keller, Designed for Growth.