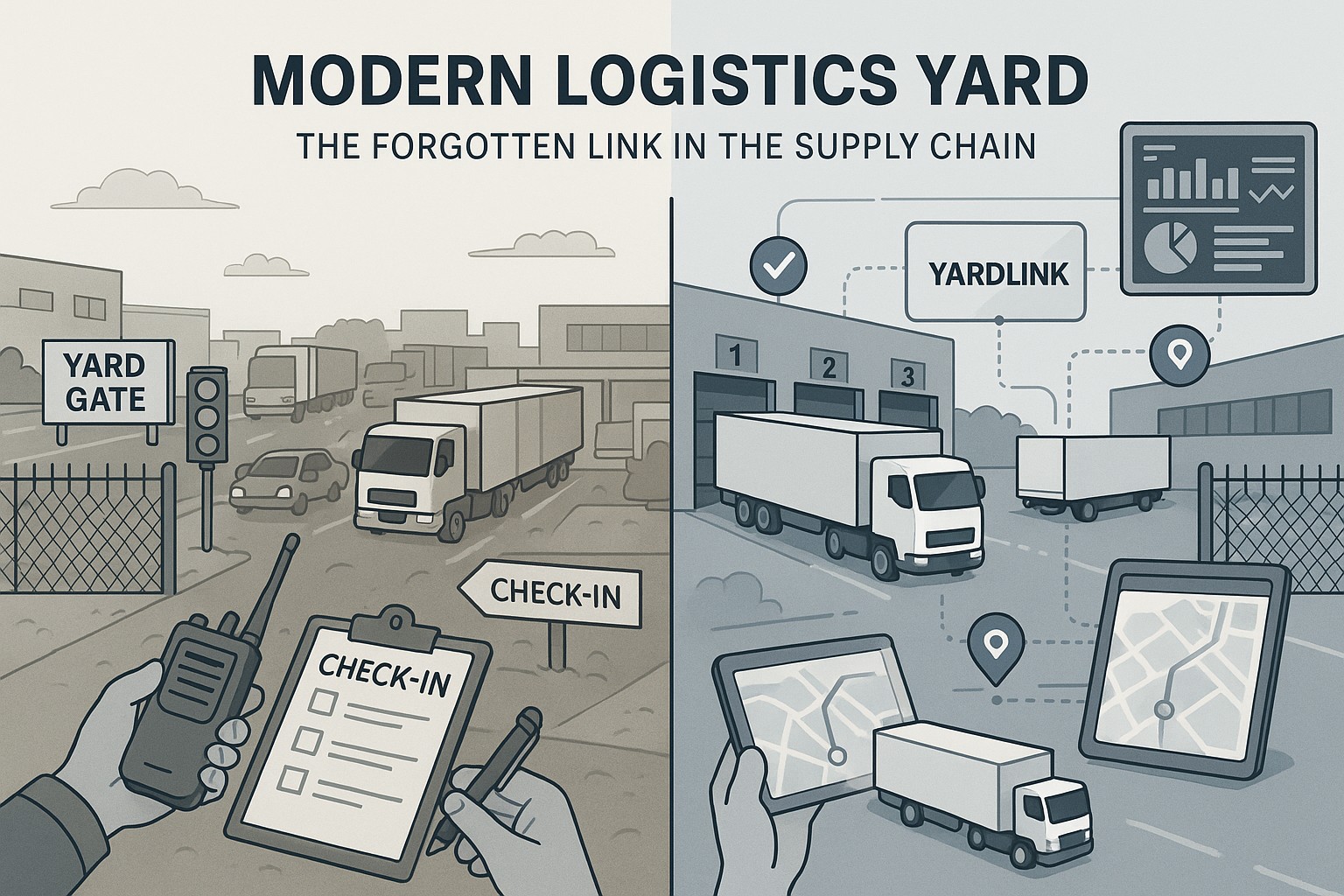

The Yard: The Forgotten Link in the Supply Chain

For all the investment poured into TMS and WMS technology, the yard remains one of the least visible and most leak-prone parts of logistics. It’s where inbound shipments bottleneck, drivers idle, detention charges pile up, and communication falls back to radios and clipboards.

At Keller Logistics Group, we’ve operated dedicated fleets, spotting, shuttling, and yard operations for decades. We know the pain firsthand. That’s exactly why we developed YardLink, a proprietary yard management system (YMS)—built by operators, for operators—to bring real-time visibility, control, and accountability to the yard.

Here are the 10 biggest yard management challenges we see in 2025—and how YardLink helps solve them.

1. Lack of Real-Time Visibility

Without live insight into trailer locations, gate status, or driver movements, yards become a guessing game.

YardLink delivers a real-time digital yard view—with dashboards showing every trailer, dock, and move in progress. Managers see what’s happening as it happens, eliminating blind spots and reducing detention.

2. Manual Coordination Overload

Paper check-ins, radios, and spreadsheets create noise, not clarity. Manual processes mean lost time and missed updates.

YardLink replaces that chaos with digital driver task management, automated workflows, and timestamps that keep moves organized and traceable.

3. Gate Congestion & Idle Time

When trucks stack up at the gate, the ripple effect hits docks and labor schedules.

YardLink will soon be equipped with gate management tools to streamline check-in/out, track arrivals in real time, and automatically capture dwell time—so bottlenecks become data-driven opportunities to improve flow.

4. Disconnected Systems (TMS/WMS/ERP)

If your yard system doesn’t talk to your TMS or WMS, data silos multiply and visibility disappears.

YardLink will be built for integration, connecting seamlessly with existing systems to align transportation, warehousing, and yard operations under one digital umbrella.

5. Trailer & Asset Tracking Gaps

Misplaced trailers are costly. So are wasted moves.

YardLink keeps a digital inventory of every asset in your yard—by status, type, and location—so your team knows exactly where equipment stands and what’s loaded, empty, or in motion. YardLink provides the ability to track OOS (out of service) trailers, with features mapped to capture OOS images and automated reporting capabilities for the status of the trailers in the yard.

6. Poor Dock Scheduling

When dock doors and yard moves aren’t coordinated, throughput tanks.

YardLink will integrate dock scheduling and yard dispatch, matching trailer movements with dock availability to maximize flow and minimize wait times.

7. Hidden Labor Inefficiencies

Without time-stamped visibility, performance metrics are anecdotal at best.

YardLink captures data down to each move, driver, and trailer, helping you identify idle patterns, eliminate waste, and balance workloads. These metrics are used to drive out labor costs to ensure your operation is running as lean as possible.

8. Site-to-Site Variability

Large shippers and 3PLs often struggle to standardize yard operations across multiple locations.

YardLink is customizable yet consistent, enabling uniform KPIs, dashboards, and best practices across all facilities.

9. Safety & Compliance Risks

Congested, disorganized yards raise risk exposure for every operator on site.

With YardLink, every move is logged and traceable, helping enforce safety protocols, minimize manual miscommunication, and protect both people and assets.

10. Lack of Accountability

When yard activity isn’t tracked, accountability fades—and costs creep in.

YardLink’s automated reporting brings transparency and performance tracking to every role: drivers, spotters, gate guards, and carriers.

Turning the Yard from Cost Center to Competitive Advantage

With YardLink, Keller Logistics Group delivers more than software—it’s a fully integrated part of our dedicated, spotting, and yard operations services. Customers gain visibility, control, and accountability where it matters most.

Same Keller reliability. Tech-driven precision.